Installing a washing machine can seem challenging, especially when considering the plumbing requirements. Yet, understanding the essential plumbing components can make the process straightforward for Homeowners can save on costly repairs and enjoy seamless laundry days by grasping the basics of washing machine plumbingrward and stress-free. Whether you're upgrading an old appliance or setting up a new laundry space, it's crucial to get the plumbing right to ensure efficient operation.

A washing machine needs three main plumbing elements: a water supply, a drainage system, and proper venting. These components work together to provide water to the machine, remove wastewater, and prevent any unpleasant odours from seeping back into your home. Each element must be correctly installed to avoid leaks and ensure optimal performance.

By grasping the basics of washing machine plumbing, homeowners can save on costly repairs and enjoy seamless laundry days. This guide will investigate into the specific plumbing requirements, offering practical insights for a hassle-free installation.

Washing machine plumbing involves a few critical components to ensure optimal operation. A water supply is the first requirement, usually delivered via hoses connected to hot and cold water taps. These hoses lead water directly into the washing machine, enabling it to fill for various cycles.

Next, a drainage system carries used water away. This involves a discharge hose that channels the water into a standpipe or a laundry tub, ensuring no backup occurs. A properly-sized standpipe, typically about 40 to 45 inches tall, is essential to prevent overflow or spills.

Finally, venting is vital to avoid water flow obstructions and foul odours. The plumbing system must include a vent pipe to release gases outside, aiding in smooth wastewater movement. Good venting ensures pressure remains balanced within the drainage pipes.

Together, the water supply, drainage, and venting—are integral to maintaining a washing machine's performance. Appropriate plumbing installation guarantees efficient water use and prevents issues like leaks or flooding, eventually protecting the home's broader plumbing infrastructure.

A washing machine requires access to a reliable water supply to function efficiently. Proper connections and water pressure are essential for optimal performance.

Most newer washing machines heat their own water so there is no need for a hot water hook-up. Cold water supply only, usuallly means a more sustainable and economical set-up because you're not calling on hot water from your boiler or cylinder that may be a fair distance from your washing machine. This way your washing machine only heats the amount of hot water you really need.

[

](https://amzn.to/3C1DUbX)

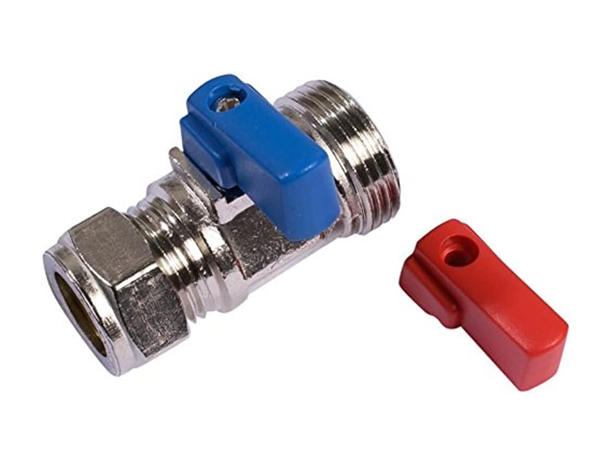

Hot and cold water connections enable a washing machine to operate effectively during various cycles. Typically, hoses connect the machine to dual taps, one for hot water and another for cold, to support temperature-specific wash cycles. It's crucial that these hoses are durable and leak-proof to prevent water damage.

My mom was an estate agent and she used to tell horror stories of washing machine supply hoses breaking while a house was empty. Horrifying the damage that unchecked leaking water can do. For that reason, she drummed into me the that never skimp on your water supply hoses. Even if you are just replacing your washing machine and had no problems with the old hose, replace it!

[

](https://amzn.to/4e0b6hs)

Water pressure, ranging from 20 to 120 psi, ensures the washing machine fills correctly. Pressure below this can result in incomplete cycles or prolonged washing time. If pressure is too high, it risks damaging the machine’s internal components. An adjustable pressure regulator or water hammer arrestor may be necessary for homes with fluctuating pressure levels.

Effective drainage is crucial for washing machine functionality. A well-designed drainage setup prevents backups and protects plumbing systems. Read how plumbing drains work.

A drain hose connects the washing machine to the home's drainage system. The hose should be secured to prevent leaks and ensure stability during heavy wash cycles. Common practice involves attaching the hose to a standpipe or laundry tub, standing approximately 40 to 45 inches tall. This height is necessary to prevent siphoning and ensures proper flow. It's vital to check that the hose connection is snug and leak-free. This should come with your new washing machine but if it needs to be replaced this is a simple and inexpensive piece to install.

[

](https://amzn.to/4eTg1lC)

The waste pipe connection needs to efficiently handle water discharge. A correctly sized U-bend or trap is essential to preventing sewer gases from entering the home. Proper venting complements this setup by maintaining balanced air pressure within the pipes, aiding effective water flow and minimizing odour issues. Always verify that these elements are correctly installed to maximise drainage performance.

[

](https://amzn.to/48cAZtf)

Powerful performance from a washing machine depends on much more than plumbing—it's about safe and efficient electrical connections. Understanding the electrical elements is crucial for optimal machine functionality.

Positioning sockets correctly ensures safety and ease of use. The socket must be within reach of the machine's power cable, generally not exceeding one meter. But, the socket should remain distant from water sources to prevent electrical hazards. Installing a dedicated circuit for a washing machine reduces the risk of overloading existing circuits. Circuit breakers rated at 15 or 20 amps accommodate the power demand safely. Residual Current Devices (RCDs) add extra protection by swiftly cutting the power if needed.

[

](https://amzn.to/3A4lKWE)

Challenges often arise during washing machine installation due to plumbing intricacies. Addressing these ensures efficient machine operation and minimises maintenance needs.

Low water pressure negatively affects washing machine performance. It prevents the machine from filling efficiently. This can lead to incomplete wash cycles.

Installing a pressure booster pump helps in regions where the water supply falls below the recommended 20 psi threshold. Regular checks on the condition of water valves and hoses are essential to ensure they aren't blocked or narrowed by sediment build-up, which hastens pressure loss.

Drainage blockages pose a frequent issue, leading to potential overflows and odours. Ensuring a correctly sized and installed drain hose prevents water back-up. Regular cleaning out the trap and vent pipe mitigates clogging, allowing for seamless drainage. Using a strainer in the washing machine's drain can catch lint and debris, reducing the chance of blockages forming within the pipes. A routine inspection is advisable to maintain free-flowing drainage systems.

You may find that you need to snake out your drain using one of the drain snake styles below. If you have a heavily blocked pipe, it helps if you have a well-placed cleanout along your pipe.

[

](https://amzn.to/4eQXGpu)

[

](https://amzn.to/40q2Fcn)

Understanding the plumbing needs for a washing machine installation is crucial for its efficient operation and longevity. By ensuring a reliable water supply, effective drainage, and proper venting, you can prevent common issues like leaks and unpleasant odours. Also, addressing electrical requirements and potential plumbing challenges can further safeguard the machine's performance and the home's infrastructure. With these insights, individuals can enjoy a hassle-free laundry experience while reducing the risk of costly repairs.

The essential plumbing components for installing a washing machine include a water supply, a drainage system, and proper venting. The water supply is connected through hoses to hot and cold taps. A drainage system uses a discharge hose to direct used water away, and proper venting balances air pressure in pipes, preventing odours and flow obstructions.

Make sure your washing machine's water supply is effective by using durable, leak-proof hoses and maintaining water pressure between 20 to 120 psi. This ensures proper filling during cycles and prevents damage to internal components from excessive pressure.

Proper drainage is crucial to prevent overflows and leaks. A correctly sized standpipe (40 to 45 inches) and a securely installed drain hose ensure stability during wash cycles. It prevents sewer gases from entering the home, enhancing the machine’s overall functionality.

Install a washing machine with a dedicated circuit rated at 15 or 20 amps to prevent circuit overloading. Ensure the power socket is nearby but distant from water sources. Include a Residual Current Device (RCD) for added safety so that power to the washing machine is cut during electrical faults.

Tackle low water pressure, by first checking valve and hose conditions for build-up. If the pressure remains below 20 psi, consider installing a pressure booster pump. Regular maintenance helps maintain optimal pressure and washing machine performance.

Minimise drainage blockages by using a correctly sized drain hose and regularly cleaning the trap and vent pipe. Consider using a strainer in the washing machine's drain to catch lint and debris, which reduces the risk of clogs. Regular maintenance is key.

Read about other Plumbing Projects You Can Do Yourself.

Try this article too: 'What Plumbing Tool Do I Need?'