Plumbing compression fittings are a staple in both residential and commercial plumbing systems, offering a reliable solution for connecting pipes without the need for soldering. These ingenious devices are favoured for their simplicity and effectiveness, making them indispensable for professionals and DIY enthusiasts alike. But how exactly do they work, and why are they so trusted?

At their core, compression fittings rely on a straightforward yet clever mechanism to create a watertight seal. By compressing a ferrule between the fitting and the pipe, they ensure a secure connection that withstands pressure and prevents leaks. This method not only simplifies installation but also allows for easy disassembly, making maintenance and repairs a breeze. Understanding the inner workings of these fittings can empower anyone to tackle plumbing projects with confidence, ensuring systems run smoothly and efficiently.

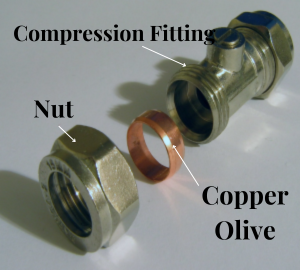

Compression Fitting With Olive

Compression fittings form a crucial part of effective plumbing systems. They provide a secure, watertight connection without the need for soldering, making them a preferred choice for both professionals and DIY enthusiasts.

Compression fittings operate using a straightforward mechanism. Each fitting typically consists of three parts: a nut, a ferrule (or olive), and the fitting body. When the nut tightens, it compresses the ferrule against the piping, creating a seal between the pipe and the fitting body. This compression establishes a reliable barrier that prevents leaks and withstands varying pressure levels without requiring heat or specialised tools.

Compression fittings find application across diverse plumbing scenarios. Common uses range from connecting copper or plastic pipes in residential water supply lines to securing fittings in commercial building systems. Their versatility extends to tasks requiring temporary or demountable solutions, accommodating easy assembly and disassembly. These fittings are also pivotal in situations where heatless connections are essential, such as when working near flammable materials.

Compression fittings consist of key components that work together to ensure a secure, leak-free connection.

The compression nut is a threaded component that secures the fitting. Made from brass or stainless steel, it tightens around the ferrule and fitting body. When the nut is tightened, pressure is applied to the compression ring, causing it to compress against the pipe and the fitting body. Proper tightening is crucial for maintaining the integrity of the seal.

The compression ring, also known as an olive, forms the seal within the fitting. Often made from brass or copper, the ring sits between the nut and the fitting body. As the nut tightens, the ring deforms slightly to create a snug fit around the pipe. This deformation is what achieves the watertight seal essential for preventing leaks.

The compression seat is the section of the fitting body where the compression ring rests. It provides a stable surface against which the ring can be compressed. Its design ensures that when the nut is tightened, the ring seals effectively. A well-designed seat enhances the overall efficiency of the compression fitting by supporting the creation of a reliable seal.

Compression fittings provide secure, leak-resistant connections in plumbing systems by compressing a ferrule against pipes. This simple mechanism ensures durable seals without requiring soldering. Compression Fittings Are Different to Sharkbite fittings which are push-fit.

In the compression process, securing the nut is crucial. As the nut tightens, it pushes the ferrule into the fitting body. The ferrule compresses around the pipe, forming a tight seal. This action creates a secure barrier, essential in preventing leaks and ensuring system integrity. Compression fittings work efficiently with copper and plastic pipes, accommodating varying sizes and diameters. Their adaptability makes them a preferred choice in plumbing.

Ensuring a leak-free connection involves proper installation. Tightening the nut adequately is vital, as insufficient tension can lead to leaks. Over-tightening may damage components, compromising the seal. Regular inspections, especially in high-pressure systems, are recommended. Inspecting the ferrule for wear and replacing worn parts enhances longevity. Using compatible materials further extends the life of the connection. By following these considerations, plumbing systems maintain optimal performance and reliability.

Compression fittings offer notable benefits and a few limitations that users should consider.

Easy Installation: Compression fittings don't require specialised tools or heat sources, making them accessible even for those without extensive plumbing experience.

Versatility: These fittings are suitable for various pipe materials, including copper and plastic. They're ideal for installations where heat application is impractical or hazardous.

Reusability: Users can easily disassemble and reuse compression fittings, providing a cost-effective option for temporary setups or modifications in plumbing systems.

Leak Resistance: A properly installed compression fitting provides a reliable seal, reducing the risk of leaks. This efficiency makes them a preferred choice in both residential and commercial settings.

Maintenance Requirements: Regular checks are necessary to ensure the nut hasn't loosened, especially in high-pressure environments where vibrations might affect the fitting.

Limited Use in Permanent Installations: Although durable, these fittings might not be the best option for permanent underground or in-wall installations as they can loosen over time.

Compression Ring Damage: Excessive tightening can deform the ferrule, compromising the seal. This could necessitate replacement of the ring or fitting to restore functionality.

Cost Factor: Over time, the reuse of damaged or worn parts might prove costly. Although initial expenses are often low, maintenance and replacement costs should be considered. How much should plumbing cost?

Proper installation of plumbing compression fittings ensures a secure, leak-free connection. Following detailed procedures influences the overall effectiveness of the installation. Get a proper cut.

Cleanliness of the pipe surface is crucial before fitting installation. Remove any dirt, debris or residuals using a clean cloth or mild cleaning agent. Ensure no rough edges exist by using a file on metal pipes or a deburring tool for plastic ones. A smoothly prepared surface enables optimal compression and minimises the risk of leaks.

Achieving the correct tightness of the compression fitting is fundamental. Hand-tighten the nut and then use a wrench to turn it no more than one and a quarter turns. Excessive tightening can damage the compression ring while insufficient tightening risks leaks. Periodic checks of the fitting in high-pressure systems guarantee ongoing reliability, with adjustments made as necessary.

Plumbing compression fittings offer a practical and efficient solution for creating reliable connections in various plumbing systems. Their design ensures ease of installation and maintenance, making them a preferred choice for both temporary and permanent applications. By understanding the components and installation techniques, individuals can confidently manage plumbing tasks and ensure leak-free connections. Whether dealing with copper or plastic pipes, these fittings provide versatility and durability, essential for modern plumbing needs. With regular inspections and proper handling, they can significantly enhance the longevity and reliability of plumbing systems, proving to be a valuable asset in any toolkit.

Plumbing compression fittings are components used to join pipes without soldering, creating a watertight seal by compressing a ferrule. Comprised of a nut, a ferrule (or olive), and a fitting body, they are easily installed and disassembled, offering flexibility and reliability in both residential and commercial systems.

Compression fittings work by tightening a nut, which compresses a ferrule against the pipe, forming a secure, leak-resistant seal. This process requires appropriate tightening to ensure effectiveness without damaging the fitting or pipe.

Compression fittings typically use brass or stainless steel for the compression nut and the fitting body, and metal or plastic for the ferrule. These materials provide durability and effective sealing when properly installed.

Yes, compression fittings can be reused, but not the Olive and in many cases not the pipe. If you're experiencing leaks it's best to begin fresh with new fittings, olive and pipe. If it's a compression isolator valve (like the one pictured above) that has been in service for years, it's best to replace that too. They can go bad.

Compression fittings are easy to install without special tools, compatible with various pipe materials, and reusable. They are ideal for situations where heatless connections are needed and offer reliable leak resistance when properly maintained.

Disadvantages include the need for regular maintenance, potential issues with permanent installations, risk of damage from over-tightening, and long-term costs associated with replacing damaged parts.

For proper installation, ensure the pipe surface is clean and smooth. Hand-tighten the nut and then use a wrench for no more than one and a quarter additional turns. This prevents damaging the compression ring while securing a leak-free connection.

Yes, but regular inspections are crucial to check for wear and ensure continued reliability. Proper installation and periodic adjustments help maintain leak-free performance even under high pressure.

If a compression fitting leaks, check for material compatibility, ensure the nut is appropriately tightened, and inspect the ferrule for damage. Replace worn components as necessary and retighten within recommended guidelines. Should I replace my copper plumbing?